Produktionsprogrammplanung und Dynamic Pricing unter Unsicherheit

| Bearbeiter | Muhannad Alturk |

| Forschungsschwerpunkt | Planung und Steuerung unter Unsicherheit |

Abstract

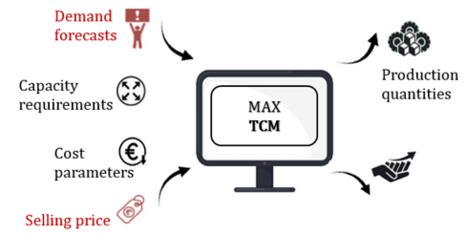

Master production scheduling (MPS) is concerned with the mid-term planning of production quantities for a portfolio of final products, which are manufactured in a series production mode. The objective consists in maximizing the total contribution margin generated from meeting forecasted demands subject to limited production capacities over a multi-period planning horizon. Despite their practical relevance, pricing decisions and demand uncertainty have been considered only rarely in the MPS literature. Based on a conceptual model, we showed how these aspects can be included within the framework of a two-stage stochastic mathematical programming formulation. Sales prices and production amounts are associated with stage-1 decision variables, whereas decisions with respect to sales volumes and the resulting inventory levels are determined at stage 2 once the actual demands for the final products have been revealed. To set appropriate prices and production quantities, we use a sampling approximation approach based on the Monte Carlo simulation of the demand values. The optimization problem to be solved in each period at stage 2 for given prices and production volumes decomposes into independent single-product Markov decision processes of a generalized revenue management capacity control type, which can be tackled efficiently by an adapted version of Belobaba’s heuristic. Computational results for a problem formulation with standard price-demand functions like a linear demand curve indicate that our two-stage sampling approximation method can provide significant improvement as compared to deterministic standard master production scheduling.