Research areas

As a goal-oriented determination of future actions, planning is subject to uncertainty resulting from the asynchrony between planning and implementation. In business practice, predictive planning models are predominantly used, which are based on assumptions regarding the future environmental conditions of the system under consideration at the time of planning implementation. In many cases, uncertain planning parameters or functions of these parameters are replaced by estimated expected values or quantiles of assumed statistical distributions.

In the case of multi-stage decision-making processes, in which planning decisions have to be made at several successive points in time, it is more appropriate to move from a rigidly defined predictive plan to flexible planning based on contingency plans. A contingency plan takes into account the temporal information structure of the multi-stage decision-making process and, at the time of planning, specifies a conditional decision for the various decision points depending on the decisions made previously and the environmental conditions realized so far. In this case, the decisions that are actually implemented are determined at the respective decision points in accordance with the flexible contingency plan, which corresponds to controlling the system in terms of influencing its behavior in real time. In contrast to the deterministic rolling horizon approach, the flexibility of control is already taken into account at all decision levels of planning.

If the uncertainty of environmental conditions can be described using random variables or stochastic processes, the planning problems can often be formulated as stochastic programs in which certain parameters correspond to random variables. Such a stochastic program must be interpreted with regard to the questions of how the solution to the problem is defined and how it is to be implemented. This is done by assigning a deterministic equivalent. In the case of predictive planning mentioned above, the deterministic equivalent corresponds to the expected value model or a chance-constrained program in which minimum probabilities are specified for the feasibility of the solution. For multi-stage decision problems under uncertainty, in particular multi-stage stochastic optimization problems such as two-stage stochastic programs with recourse or Markov decision problems are used.

As part of our research, we use stochastic optimization models and methods for planning problems in the areas of production, maintenance, and renewable electricity generation. For medium-term production planning, we have developed a novel formulation of the problem of integrated master production scheduling and pricing of end products under uncertain demand. The decision model is based on a nonlinear two-stage stochastic program, in which production quantities and sales prices are determined by sampling approximation in the first stage, and the second stage is solved as a Markov decision problem. Experimental performance analyses show that, compared to traditional predictive planning approaches, considerable increases in contribution margins can be achieved, while at the same time significantly improving the forecast quality of the realized contribution margins. We use different types of Markov decision problems to control automated flow lines with flexible workpiece buffers and to control renewable energy systems of regional suppliers, which, in addition to electricity generation plants, also use large battery storage systems and participate in continuous intraday trading on an electricity exchange.

Both reinforcement learning methods and exact approaches based on the evaluation of functional equations are used as solution methods. To optimize budget allocation for multi-period maintenance planning of modular systems, a problem formulation was developed as a Markov decision problem with uncountable state and action spaces, which is solved using a deep deterministic policy gradient algorithm.

PhD project:

- Buffer control in stochastic flow lines

- ADP approaches for the control of renewable energy systems

- Master production scheduling and ynamic pricing under uncertainty

- Multi-period budget allocation in the maintenance of modular systems: A use case of deep reinforcement learning

Businesses take place in networks like intra- or interorganizational supply chains. In such a network, various economic actors with private information and independent goals use shared resources or participate in joint value creation and sales processes. Due to the asymmetric distribution of information and objectives, centralized planning approaches are not feasible in such cases. Instead, processes must be coordinated using appropriate mechanisms for decentralized coordination. Despite the self-interested behavior of individual units and the lack of complete information, the mechanism should optimize the social welfare of the network under requirements for fairness and voluntary cooperation.

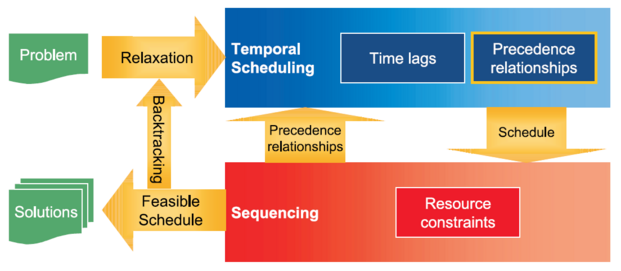

As part of our research, we investigate decentralized coordination problems that arise when scheduling globally distributed projects in large companies and corporate groups. A second application area is the cooperation of independent companies in reverse supply chains for waste electrical and electronic equipment. For decentralized project scheduling, we develop auction-based mechanisms for the efficient allocation of central resources with limited capacity, such as development engineers or capital-intensive equipment. Unlike other approaches, we take into account generalized precedence relationships between activities in the form of prescribed minimum and maximum time lags. This requires the development of novel decentralized temporal scheduling methods and an innovative design for a combinatorial auction in which, instead of the usual usage rights in specific time periods, sets of precedence relationships between activities of different projects competing for central resources are auctioned. For the coordination of reverse supply chains, we design generalized capacity reservation contracts between the manufacturers of the primary products, who are responsible for the return of waste electrical equipment, and collection companies that actually carry out these returns on behalf of the manufacturers and on the instructions of the German Waste Electrical Equipment Register (EAR). By integrating a value-at-risk condition, it is possible to limit the manufacturers' financial risk in investing in collection options. For different versions of Stackelberg game scenarios, it can be shown that, under economically plausible assumptions, the capacity reservation contract can coordinate the reverse supply chain, i.e., maximize social welfare of the network.

PhD project:

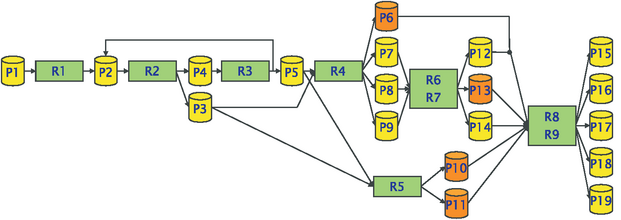

A scheduling problem consists of determining the execution time intervals for a set of operations, taking into account the limited availability of production factors. In operational value-added planning, scheduling problems occur as project planning problems in research and development and as scheduling, capacity planning, and machine allocation planning problems in production planning. In a resource-constrained scheduling problem, operations typically take more than one unit of production factors each to execute. The factors of production are then called resources, where renewable resources correspond to potential resources and storage resources correspond to repetitive resources.

As part of our research, we conduct fundamental structural studies for different types of resource-constrained scheduling problems, based on which we develop exact and heuristic solution methods. In particular, this includes methods for scheduling projects that are subject to complex constraints such as minimum and maximum time intervals between activities, overlap-dependent activity durations, or interruptible activities. The concept of storage resources we have developed allows the integration of material availability and storage capacity constraints, which play an essential role in many practical scheduling problems. Scheduling problems with storage resources have found their way into numerous research projects of other research groups and into industrial planning systems worldwide.

PhD project:

- Resource-constrained project scheduling with interruptible activities and generalized ordering relationships

- Planning of research and development projects in the semiconductor industry

- Auction-based coordination of decentralized project portfolios

Benchmark instances: Project generator ProGen/max

When planning the execution of operations that are assigned to different locations in a network and share resources, decisions have to be made about the execution time intervals of the operations(scheduling problem) and the transport of resource units between the locations(routing problem). Such routing and scheduling problems arise, for example, in the planning of cross-site production processes in supply chains, the planning of ambulatory care services, or the planning of a spatially distributed project portfolio. Due to the strong interdependencies between the scheduling and routing decisions, the hierarchical decomposition into two subproblems often leads to inefficient solutions. If the two subproblems are considered in a joint model, an integrated routing and scheduling problem exists. Such an integrated problem is harder to solve due to its higher inherent complexity, but fully represents the potentials of optimal coordination between scheduling and routing decisions.

In our research, we develop the resource transfer problem as a generic modeling framework for integrated routing and scheduling problems. The resource transfer problem consists of determining the occurrence times of spatially distributed events that affect the availability of renewable and storage resources. Each event must be assigned quantities of appropriate resource units. For pairs of events, minimum and maximum time intervals, transfer times for shared resource units as well as incompatibility and inclusion relations of the allocated resource quantities have to be considered. A large number of different problems from the areas of route scheduling, machine allocation scheduling and resource-constrained project scheduling as well as their combinations can be represented in this reference model and numerous requirements of practical routing and scheduling problems can be considered. In addition to model development, we are engaged in the design of constraint-based solution procedures for resource transfer problems.

PhD project:

The subject of plant utilization planning is the short-term resource utilization planning of multi-stage process plants in which different products can be manufactured successively or simultaneously. Such plants are used for the production of high-quality fine and specialty chemicals as well as active ingredients whose sales volumes are comparatively small and fluctuate over time. With regard to the repetition type of production, a distinction can be made between market-related variety production of product variants on multi-product plants and order-related batch production of different product families on multi-purpose plants. Variety production is typically characterized by continuous process control and plant operation in campaign mode, while batch production is often associated with discontinuous process control and mixed operation.

Starting point of the plant layout planning are given primary requirements of the final products, which are produced in several process steps on the equipment of the plant under consideration. The plant layout planning includes the determination of a suitable quantity of necessary process step executions(quantity planning) and their scheduling on the equipment of the plant(sequence planning). Numerous technological peculiarities of process engineering production such as mixing and joint production, lower and upper limits for batch sizes, flexible input quantity and output quantity ratios, variable production rates or durations of process steps, sequence-dependent changeover and cleaning times, limited storage capacities as well as expiry and post-lay times for intermediate products must be taken into account. Therefore, problems of plant layout planning show a considerable complexity. In our research, we develop efficient methods for the scheduling of flexible multi-purpose and multi-product plants for both batch and variety production. In contrast to the total models of mixed-integer optimization documented in the literature, we follow a hierarchical decomposition approach, which decomposes the planning task into the quantity planning and the sequence planning. Suitable modeling techniques and methods of mixed-integer linear and nonlinear optimization are used for quantity planning. Against the background of uncertain planning data, approaches of predictive-reactive planning are investigated for plant allocation planning, which suitably combine methods for quantity planning and methods for sequence planning under uncertainty. For real-time applications of sequence planning such as short-term capacity availability checks, priority control methods for online optimization are used, which allow a particularly efficient incremental scheduling of production orders.

PhD project:

Configuring a storage system can be broken down into five major tasks:

- Determining the storage bin allocation strategy

- Dimensioning and allocation of storage capacity to articles or article groups

- Design of the storage technology and layout planning

- Determination of the storage and retrieval strategy

- Design of the conveyor system

While the storage bin assignment strategy defines the principle according to which possible storage bins can be assigned to the articles, the dimensioning and allocation of the storage capacity determines how many storage bins are to be set up and which storage bins the individual articles can access if no free storage bin assignment is planned. Next, a decision must be made about the storage media and storage aids to be used (storage technology) and a physical position in the warehouse must be assigned to each storage bin and the putaway/retrieval points (layout planning). The putaway and picking strategy defines how putaway and picking orders can basically be executed in the site. This includes the rules for forming the work cycles of the conveyors and the rules according to which suitable storage bins are assigned to the orders. Finally, the type, number and performance parameters of the conveyors to be used must be determined in the design of the conveyor system.

The subject of our research are models and methods to support capacity dimensioning and allocation as well as the design of the conveyor system for different combinations of storage bin allocation as well as storage and retrieval strategies. In this context, the storage space requirements are modeled as random variables and the arrivals of storage and retrieval orders as stochastic processes. For the resulting stochastic optimization and analysis models we develop efficient methods of mathematical programming and characteristic analysis of stationary Markov processes. In further investigations, we are interested in the dependencies between the individual subproblems of the bearing configuration and possibilities to consider them in a feedback planning approach.

PhD project: